Accredited degree program

Additive manufacturing - materials, development and lightweight construction

Bachelor of Engineering

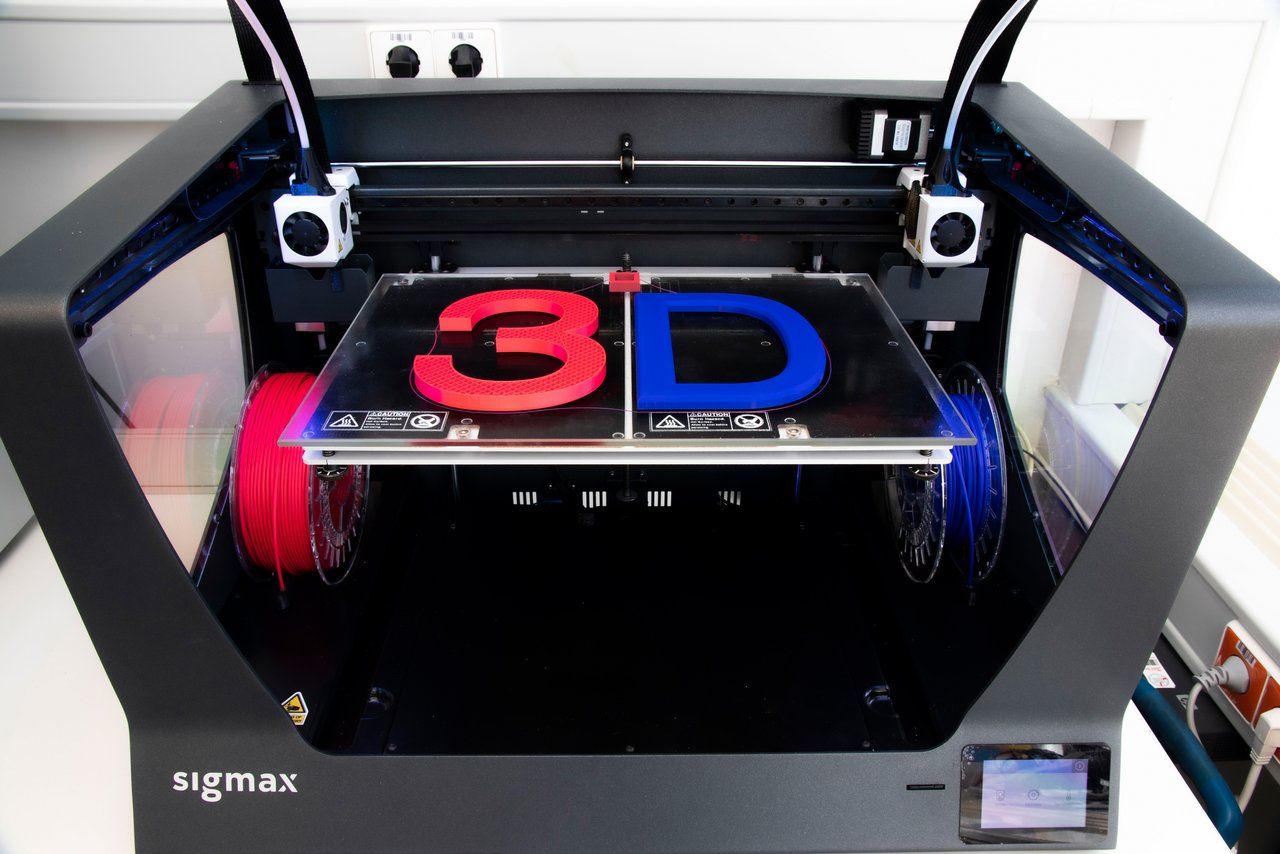

The degree programme offers core competencies in additive manufacturing (3D printing) on a solid mechanical engineering foundation.

| Start | Winter semester |

|---|---|

| Admission Criteria | Open admission (no numerus clausus) |

| Application period | - |

| Study format | Full time, with in-depth practical experience, Joint degree programme |

| Study cost | None (only semester fee) |

| Normal duration | 7 Semester |

| Language | German |

| ECTS | 210 |

| Accredited degree program | |

| |

21 min.

# 34 - Wir studieren Additive Fertigung - Werkstoffe, Entwicklung und Leichtbau

Erfahrungen aus dem Studium

Play PodcastThe study programme / profile

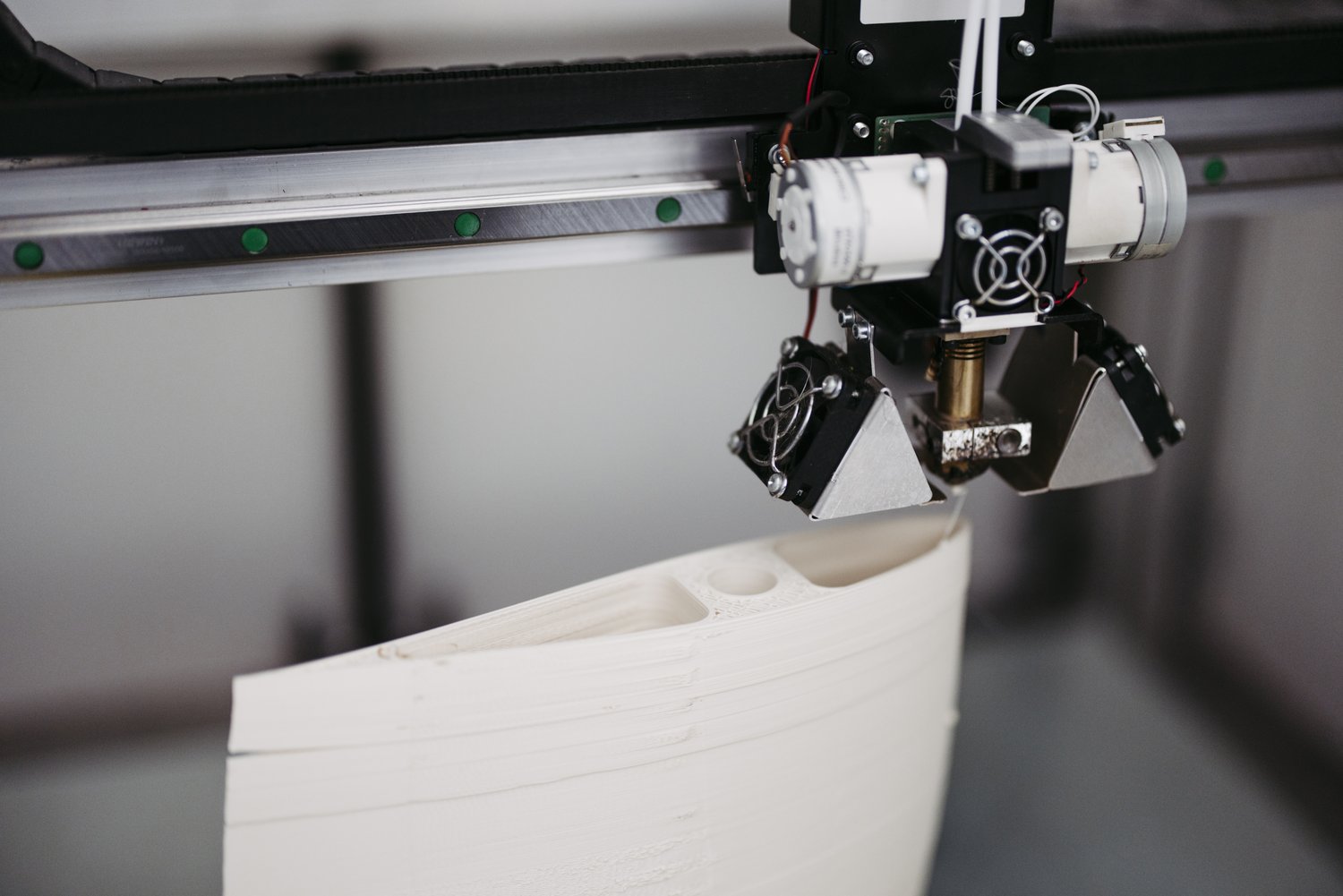

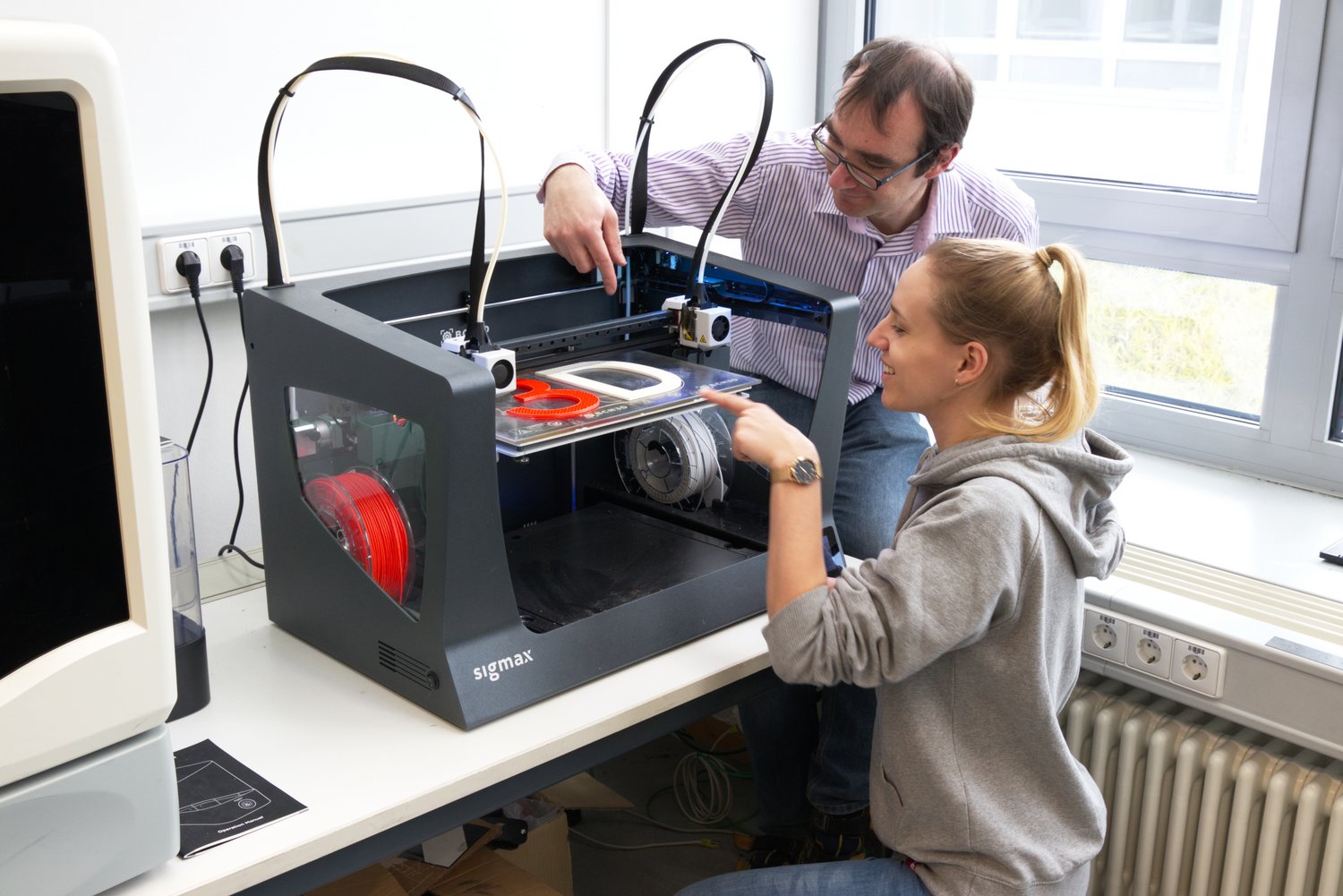

The degree programme includes numerous core competencies in additive manufacturing (3D printing) based on a solid foundation in mechanical engineering and, in addition to specific material and process engineering knowledge, primarily teaches what is known as "additive thinking". This means that the new design freedoms of additive manufacturing (3D printing), which are of particular importance for the key technology of lightweight construction, are specifically trained. The Lightweight Construction and Production and Quality Management profiles offer in-depth study and specialisation, depending on individual inclinations.

The wide range of career opportunities and job offers extends from mechanical engineering to medical technology, from the automotive sector including the production and supply industry to aerospace engineering. Furthermore, the degree programme is a good starting point for various technical Master's programmes, such as the Master's in Lightweight Construction and Simulation.

Contents and course of study

The degree programme comprises six theoretical semesters and a practical semester in the fifth semester. The first three semesters teach basic sciences such as engineering mathematics, materials science and design, while this knowledge is deepened in the fourth semester. From the fifth semester onwards, the profile is formed by choosing one of the specialisations: Lightweight Construction or Production and Quality Management. The programme concludes in the seventh semester with the completion of a Bachelor's thesis. Practical training in industrial companies and technical institutions takes place outside the university, supervised by the university and supplemented by practical courses. The pre-study work placement lasts six weeks and the industrial placement in the practical semester lasts 80 days.

Learn moreDual study programme

The dual study programme is a practice-oriented form of study that combines theoretical course content at universities with professional practice in a company. During their dual study programme, students complete both lectures at the university and practical assignments at the company, allowing them to acquire both academic knowledge and practical experience at the same time.

Prospects after graduation

After completing a Bachelor's degree in Additive Manufacturing - Materials, Development and Lightweight Construction, career prospects open up that are similar to those of mechanical engineering graduates, but with a clear specialisation in additive manufacturing technology, where there is currently a shortage of skilled workers. Graduates can work in various areas such as product development, project management, quality control and research, whereby their expertise in innovative manufacturing technologies and lightweight construction is particularly in demand.

Requirement profile

A requirements profile for the degree programme can help to identify the specific qualifications, skills and characteristics that are recommended for successful participation in the degree programme. For the Bachelor's degree programme in Additive Manufacturing, these are as follows:

- Interest in a young, dynamically developing 3D printing technology

- Creativity, inventiveness, open-mindedness towards innovation

- Enjoy working with digital media

- Solution- and goal-orientated thinking and action

- Technical affinity

- Enjoy working in a team