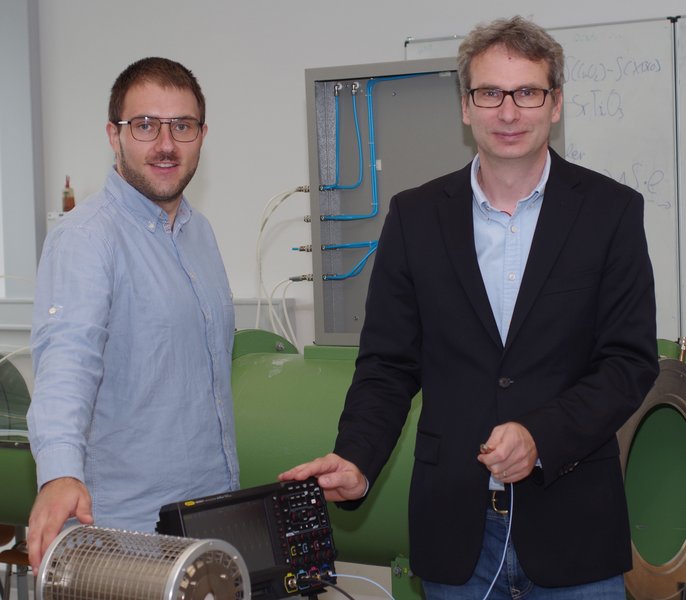

Steel is needed to make machines or tools. The steel is machined, formed and pressed at high temperatures. The temperature must also be kept constant and closely monitored during many processing steps. If this is not the case, it can lead to defective components and high costs for reworking. To prevent this and improve processes in the steel industry, Landshut University of Applied Sciences is developing a new contactless temperature sensor as part of the “AtoFurnance” research project. This enables a much faster and more precise measurement than before. The research team led by Prof Dr Tim Rödiger from the Faculty of Mechanical Engineering wants to use it to make steel processing more efficient, improve material quality and reduce energy and production costs. The two companies LKM electronic GmbH and automatic Klein GmbH are participating as industrial partners. The Federal Ministry for Economic Affairs and Energy is providing Landshut University of Applied Sciences with funding of 220,000 euros for the project, which runs until the end of 2023, as part of the “Central Innovation Programme for SMEs”.

Measurements in microseconds

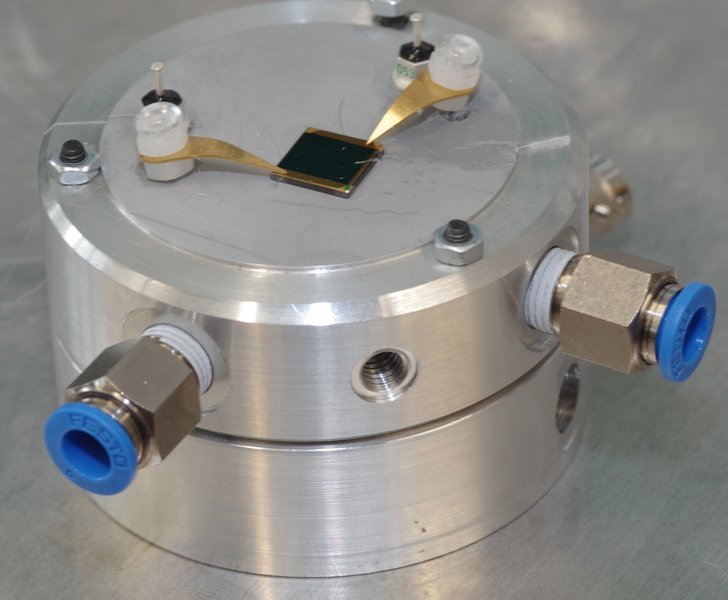

“For the energy transition to succeed, it is essential to increase energy efficiency and drive savings in energy-intensive industries”, says Rödiger. The Landshut professor therefore sees great potential in the new measuring system for steel processing. The device, based on ALTP sensors (atomic layer thermopiles), makes it possible to measure temperatures and heat flows in a time resolution of microseconds and therefore sets itself apart from previous measuring devices. The sensor is modified and calibrated to act as a radiation thermometer. “This works similar to a clinical thermometer for the forehead,” explains Rödiger, “we use it to measure the surface temperature, only much faster and at a much greater distance.”

Quality loss due to temperature fluctuation

“The fast and precise measurement should help make processes in the process chain run faster and more efficiently in the future”, explains Rödiger. Slow process sequences usually lead to a lot of energy being lost, the surfaces oxidising and the quality of the components often deteriorating as a result. The consequence: the material either has to be reworked mechanically at great expense or does not meet the quality requirements and is disposed of as a reject. Both cost the industry a lot of money.

Saving energy and increasing efficiency

The new measuring device should make it possible to optimise the processes in the hot steel presses and, for example, adjust the temperature or the contact pressure accordingly. The speed of the measurement has a direct influence on the material quality. “This would allow companies to reduce their costs and increase product quality at the same time”, says Rödiger, summarising the advantages of the new measuring system. In cooperation with the two industrial partners LKM electronic GmbH and automatic Klein GmbH, the researchers want to develop a demonstrator and new process strategies by the end of the project.

About the project

The “AtoFurnace – development of an ALTP temperature sensor to monitor steel processing” project will run until the end of 2023. Prof Dr Tim Rödiger from Landshut University of Applied Sciences is responsible for the overall project management. The project partners are LKM electronic GmbH from Geratal and automatic Klein GmbH from Essen. The Federal Ministry for Economic Affairs and Energy is providing Landshut University of Applied Sciences with funding of 220,000 euros as part of the “Central Innovation Programme for SMEs”.

Project name: | AtoFurnace |

Project partners: | Landshut University of Applied Sciences LKM electronic GmbH, Essen Automatic Klein GmbH, Essen-Steele |

Overall project management: | Prof. Dr. Tim Rödiger, Landshut University of Applied Sciences |

Funding for Landshut University of Applied Sciences: | 220,000 euros |

Programme: | Central Innovation Programme for SMEs (ZIM) |

Funding: | Federal Ministry for Economic Affairs and Energy |