In the cell production laboratory, industrial cells in pouch format from 30 mAh to 2 Ah can be produced by hand. A manual sample line is available for the production of lithium-ion cells as single or bicells. The cell composite is assembled using free stacking, roll lamination or, if required, Z-folding.

As part of the CompStor project, semi-automatic partial production stations for trimming and arrester welding, housing sealing, electrolyte filling, degassing and finalisation as well as a database system for digitalisation were added.

In conjunction with the resources of the electrode production/cell testing/analytics laboratories, comprehensive material and process analyses can be carried out on various components of lithium-ion cells.

Equipment:

Manual cell production

- Manual punches

- Mechanical knuckle-joint presses for steel strip separation Mäder presses EP 750-40

- Amtech Ultraweld 40 ultrasonic welding machine

- Laboratory sealer Kopp SGPE 3000 (jaw length 300 mm)

- BINDER VD 53 vacuum drying oven (up to 200 °C)

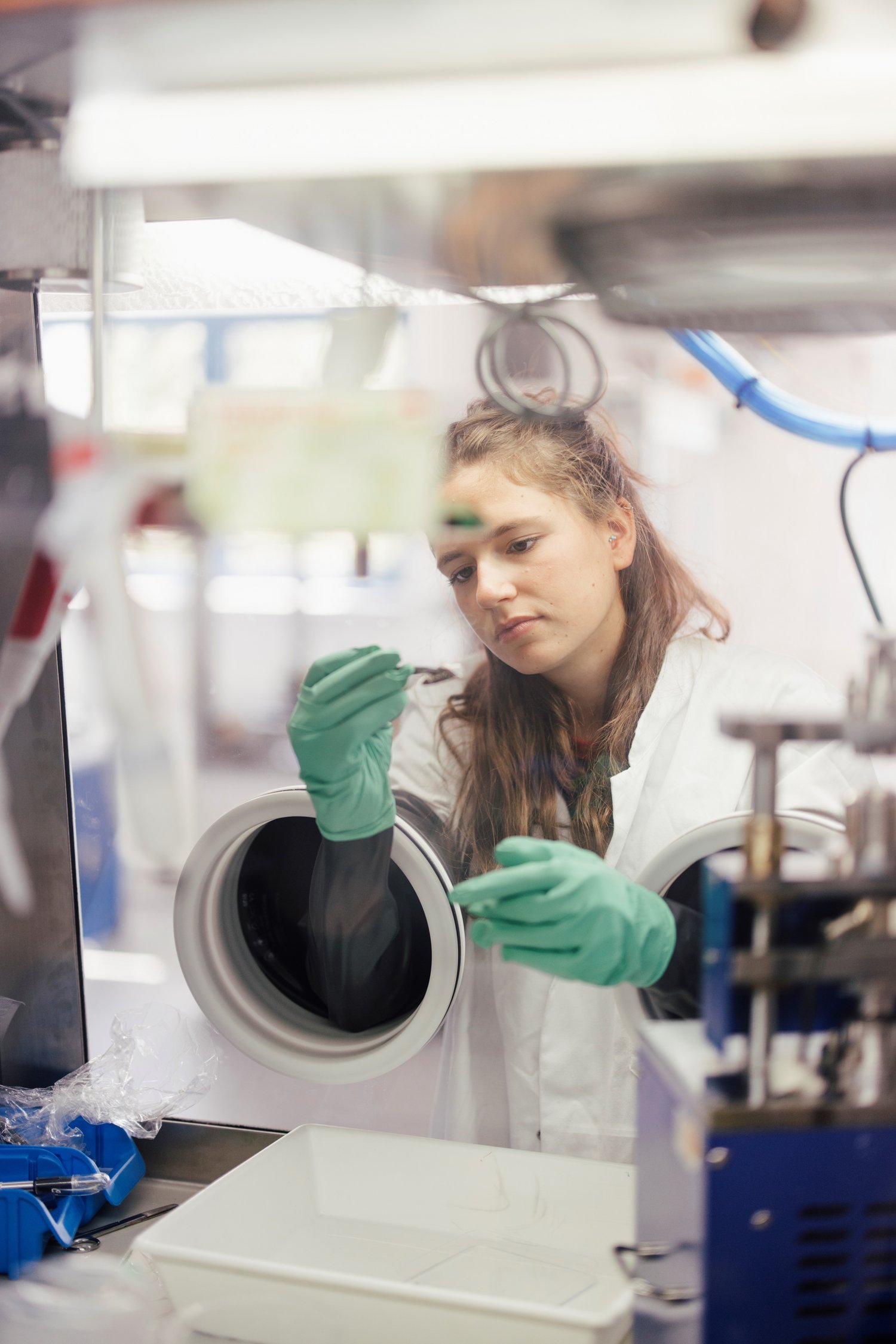

- Glovebox MBraun MB20 (Ar 5.0, 2 gloves, H2Oand O2 < 0.1 ppm)

- Electrolyte filling system FMS Systemtechnik (in room atmosphere)

- Vacuum sealer Komet Vacuboy

Semi-automatic cell production

- Pneumatic toggle press for steel strip separation Mäder presses APK 4 L

- Roller laminator Manz Italy (formerly Arcotronics Italia) BLE 282 D

- Trimming and arrester welding station Sovema UWT250

- Station Pouch housing sealing Sovema PCS250

- Glovebox MBraun MB200B (Ar 5.0, 8 gloves, H2Oand O2 < 0.1 ppm, heatable sluice)

- Electrolyte filling system (in glovebox) Sovema MFC250

- Degassing and finalisation station Sovema DSU 250

Other

- Z-Falter Harro Höfliger HH - 4428.001